1.

Remove the cylinder heads following the instructions in the workshop Manual section 12, inspect the cylinder block face, cylinder bores and bolt holes are free from debris.

2.

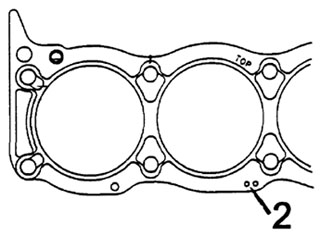

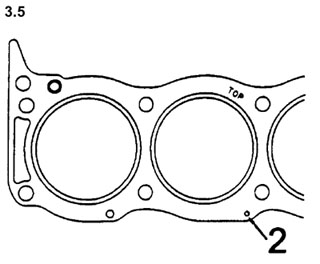

Select the appropriate gasket for the type ofengine ie: 3.5/3.9 or 4.2. This can be identified by the identification holes in the gasket, 3.5 has one hole, 3.9/4.2 has 2 holes. See illustration below.

|

|

3.

Fit and position the gasket on the dowelsensuring that the word

TOP

is uppermost.

DO NOT FLEX or BEND THE GASKET.

4.

Ensure the gasket and cylinder head face are clean and free from grease and debris, carefully fit the cylinder head.

5. NEW CYLINDER HEAD BOLTS MUST

ALWAYS BE FITTED.

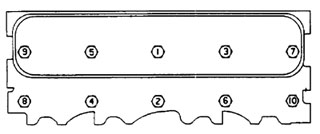

Check the bolt threads fordamage, lightly oil the threads. There are twolengths of bolt which must be fitted to theappropriate position as shown in the illustration.

Flange bolt length 66mm is fitted to holes2,4,6,7,8,9 and 10.

Flange bolt length 96 mm is fitted to holes 1,3 and5.

6.

Lightly tighten all bolts in the numbered sequence shown above.

7.

Tighten all bolts in the sequence shown to 20 Nm (15 lb ft.).

8.

Tighten all bolts in sequence a further 90û(1/4 turn).

9.

Tighten all bolts in sequence a final 90û(1/4 turn).

|